技術開發或移轉的活動在晶圓製造工廠是一個需要資源整合, 跨部門協調合作的龐大工程, 限於人力, 物力, 大多的工廠都會在既有的生產線同時去做技術開發或移轉, 所以牽涉廣泛, 必須要有作業指導書規範此類活動, 如何在工廠內進行? 通常每一個新產品(技術)導入從可行性評估...到試量產都視為一個專案, 若從專案的角度看: 品質, 成本, 交期三大指標.品質須符合客戶要求, 成本要控制在預算內, 交期即是在預估的時間內完成.

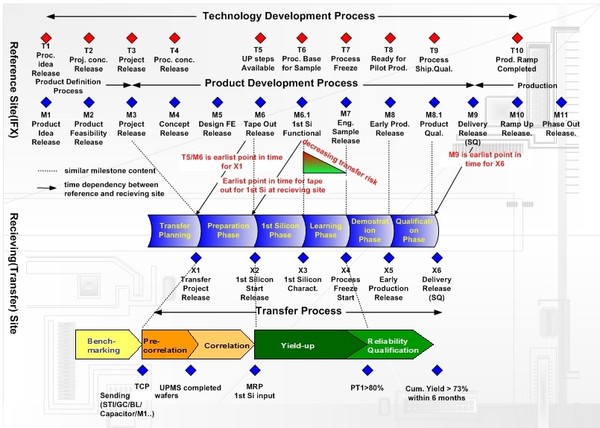

對於技術開發或移轉如此複雜的活動,每家公司都會有流程管理的步驟,其中了許多細節環環相扣,好像大隊接力, 考驗公司內部組織運作的溝通與協調, 是否能執行圓滿完成? 以下是流程的示意圖:

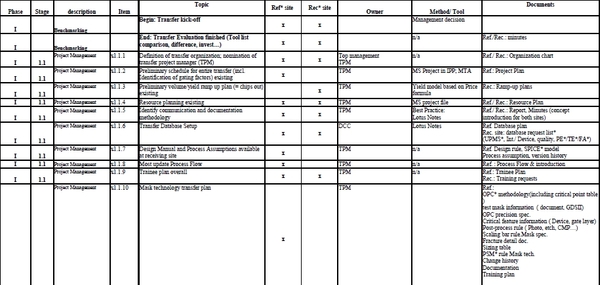

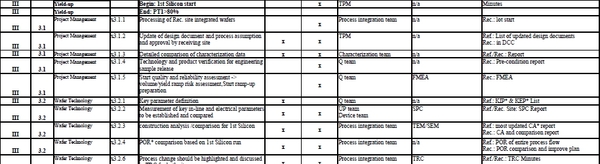

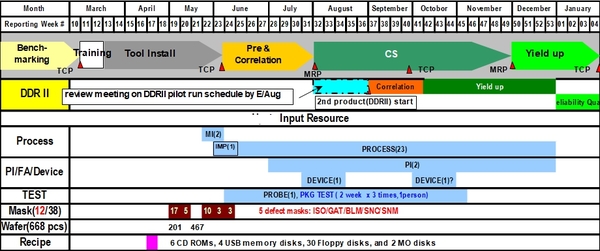

若化成執行的項目, 以技轉為例: 分為5個階段:

(1)benchmarking之前主要做marketing和technology方面的可行性評估,分別由sales和TD兩個單位提出評估報告給經營負責人決定是否要進行下一階段

(2)benchmark(transfer kick-off~~tool list comparison, difference, invest...), 大部分是paper work,依據新產品所需的特性,準備電性和製程必要的規格,如果有新製程或測試程式需要開發,TD也必須在試產之前就緒

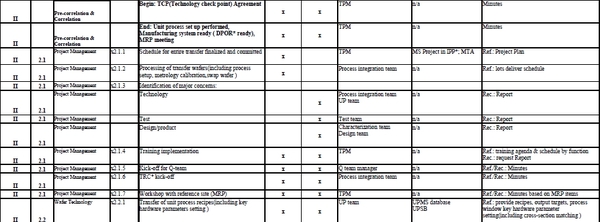

(3)pre-correlation(TCP agreement ~~UP setup & manufacturing system ready),生產系統/機台端/製程管制系統上線就緒

(4)yield up(1st Si start~~yield targeting), 從1st Si開始到線上製程凍結為第一版,此時的目標視新產線的製程與良率的穩定度, 風險量產是慢慢增加新產品的產量,同時產線上一切有關產品的製程和測試,其改變都要納入管制,用來檢視良率改善與否的相關性,同時開始挑選qual. lot作為新產品驗證的候選

(5)reliabiity qualification(SQ start to completed): 品質驗證及量產,此時除了線上的良率達標外,另外的重點是驗證可靠度及新產品特性是否符合市場要求(即原先評估報告中所提的目標)

以下用一實例說明:

2004/12/21

H company transfer training review & discussion

Workshop cover checklist items.

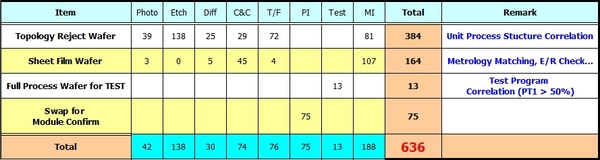

Wafer requirements

Send material ahead to study before trainingQ&A in training

Training content of each function from H company

According to organization and job function, negotiates training quota with H company by P company requirements.

Goal: complete technology transfer, Integration need to work out with DCM/YE/PFA/Device

P company feedback on Dec. 23.

1. ask 1:1 conference call

2. H company training program of each function before telecom, discuss & negotiation in telecom.

3. training summary.

Project management: transfer schedule, process flow update

Dec. 23rd, database setup issue

1. need H company supporting copy option from website.

2. need access to H company database from P company and replicate routinely

3. or create a path to replicate information of H company database

4. bottom line: P company has its own database finally.

Dec. 28th Training program

H company request: P company proposal, telecom schedule

Photo: document study before training, manpower arrange(DM+SM if 3 fixed)

Diff: ALD Al2O3, WSix in TF area, document issue, one more person backup.

TF: not clear proposal/table, 2 for CVD, 2 for Metal.

C&C: total 4 persons.

Etch: send one more person for strip process in clean training, or ask for ashing process in training table.

Probe: PE/FA, PE/TE product weakness testing coverage.

2005/01/06

TCP workshop: focus on prre-correlation, design and project; training and workshop time.

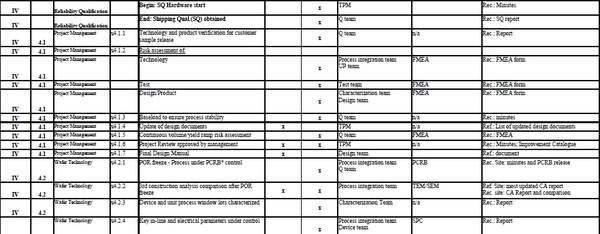

Benchmarking summary: Org. chart, MTA, resource plan, DB status setup—UPMS setup, training plan, mask plan.

Jan. 26th DB(database) control and setup

DRM system—read only and record automatically

-

document classification: collaboration system—document directory

-

document type(word, excel, pdf…)

-

content(all English version, or including descriptionfile exchange)

-

DB structure and org. chart

-

password constraint release

-

working file

AR: classification by spider tree, document grouping

-

spider search and structure.

Document control in H company

-

MIS use DRM system to every PC and individuals

-

No laptop used in office

-

Read only function available, no download option.

-

Encoded file in H company system

-

P company site

1. open PCS accounts to P company members: DCC group: download/upload, member list group: read only function released

2. data to data copy: need to setup and refresh PCD through XML description by H company.

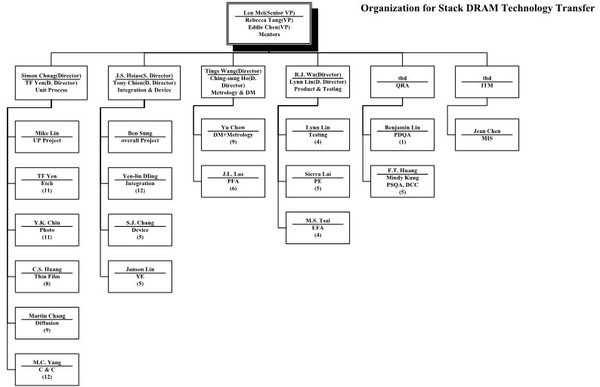

Transfer milestone: benchmark Mar. 7th, correlation May 30th, Yield up Aug. 1st, Qualification(CS) Aug. 29th.

Apr. 11th-12th workshop

-

HDP DED process: current tool AMAT, target tool Novellous

-

Oxide etcher: chamber arcing still no solution to defect issue

-

GC_CD U% getting worse because of SG process addition

-

LPC open issue: extend etch time during WSix etching to avoid WSix bottom extrusion.

-

BL P.R. budget not enough, ADI~97nm

-

M1 sidewall loss in etching

-

Serious loading effect(dense vs. loose) on Pfet variation @gate spacer TEOS

-

Coin defect of BL spacer SiN

-

Rc_LPC by doped POLY trade off between tWR(high Rc) and tRAS(low Rc)

-

higher ToinB temp. sacrifice Rc_N+/P+

-

ILD2 HDP: PID(Plasma Induced Damage), plasma charging at high temp. low temp. Novellous e-chuck performance worse than AMAT.

-

Void check: inspection after additional BOE dip and CMP

-

ILD1B BPSG gapfill capability relate to LPP bridge because of BPSG void

-

SN PSG: 1)P2O5 interface segregationPOLY bridge, 2)necking

-

M1 BM TiCl4 suffer leakage.

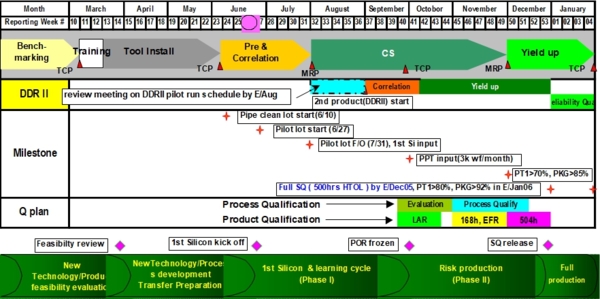

Jun. 1st total 40 masks, 8 defect masks(7 DUV+1 i-line) for pipe clean/MES, IUI, EAP ready for POR/LPP bridging issue on 3x3 shot lots

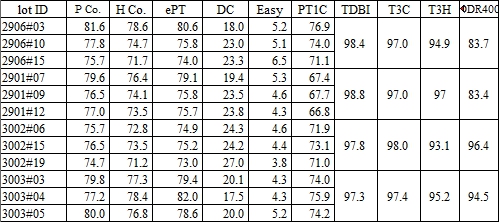

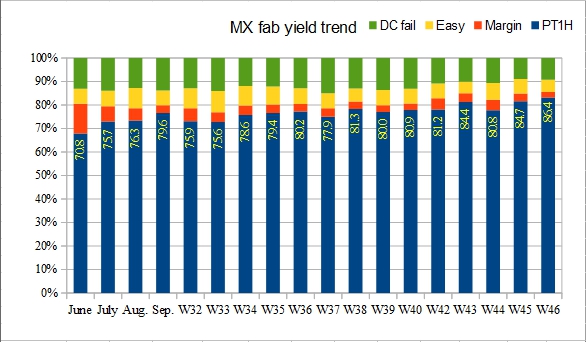

Jun. 2nd M10 yield~80% on 2 FO 2x3 lots/ 72% PT1, 82~85% ePT1, 10~15% DC fail.

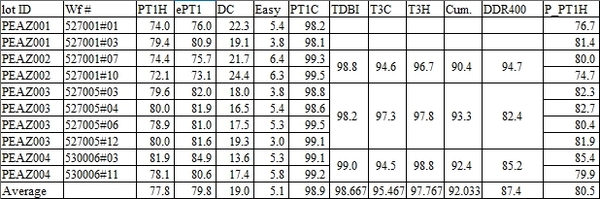

Sep. 6th LAR lots yield: PT1H 77.8, PT1C 98.9, PKG cum. 92, DDR400 87.4

Sep. 7th F3 ramp-up inline wafer~3900pcs, SD9B~200pcs

DDR400 issue: Rc_BL at periphery higher than MX, GT_CD 5nm larger than MX/ Tck issue

Sep. 28th DC yield detractor

Margin:

Easy fail: SNC_BL SAC/LPC not open/SN bridge

DC fail: BL bridge/CMP scratch/Metal particles

Process change for flowing LPC not open @LPC BO WET without bath circulation.

Recieving site WIP~5600pcs

Oct. 17th W41

Major failure:

Easy fail: SNC_BL SAC/LPC not open/SN bridge

DC fail: BL bridge/CMP scratch/Metal particles

SN Hard Mask CD variation tighten from 4nm to 3nm, improved by etch recipe modification in BARC etchstop

Oct. 11th Qual. Lot PT1/PKT result